Belt Arrestors

The Belt Arrestor is a 100% mechanical device, which is designed to operate only if there is loss of tension in the belt. There is no hydraulics, pneumatics or electrics which may add additional maintenance problems; it works by using the tension of the belt to keep the device open with mechanical counterweights. As soon as there is loss of tension in the conveyor belt (due to it being snapped or broken) the counterweights engage which activates the Belt Arrestors “jaws”, snapping shut almost immediately and prevents the top and bottom belts from running down the incline.

Safety first – if an inclined conveyor belt breaks and the belt is not arrested (caught) immediately, due to the belt and material rolling back, it could result in an injury or fatality to personnel and damage to the conveyor system as well as any surrounding infrastructure.

Minimises downtime – prolonged downtime in the production process as a result of a belt breakage that runs back down the incline is reduced by up to 90% as a result of the arrestors being fitted, therefore minimizing the decrease in productivity and lost income. This system can pay for itself with one belt breakage!

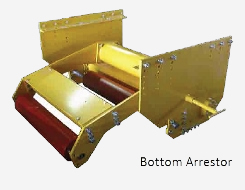

There is a top and bottom arrestor, which traps both the top and return conveyor belt and prevents it from running back down the incline. Both ends are then in close proximity to facilitate easy splicing.

Top Arrestor: is used on the carry side of the conveyor belt and is installed as close as possible to the head pulley as possible. It exerts a positive clamping force of up to 60 ton.

Bottom Arrestor: is only used on Head Drive conveyor systems. The bottom arrestor activates immediately with the Top Arrestor and prevents the belt and counterweight from running away. It exerts a positive clamping force of up to 20 ton.

Slipping Device: is installed where the drive of the belt is situated at the middle of the belt (normally named a Tandem Drive), these drives normally take 8 to 10 seconds to come to a standstill once the belt has broken or snapped. The slipping device works like an ABS braking system which holds the belt immediately and lets the belt slip through the device until the drives have come to a stop, thereafter the Slipping Device holds the belt and prevents it from running away. It exerts a constant braking force of up to 2.4 ton.

Location

MES International

Walton New Road

Bruntingthorpe

Lutterworth

LE17 5RD

Company Registration Number 1556587 - Vat Number GB 355 3697 25

Web Design Leicester